I know a lot about Lean. In this article we re going to look at another aspect of lean manufacturing Training Within Industry TWI . Through a train-the-trainer program supervisors were taught to train and lead their people in the right way.

Throw out any lean term and I ll define it describe it and explain its place in the lean toolbox.

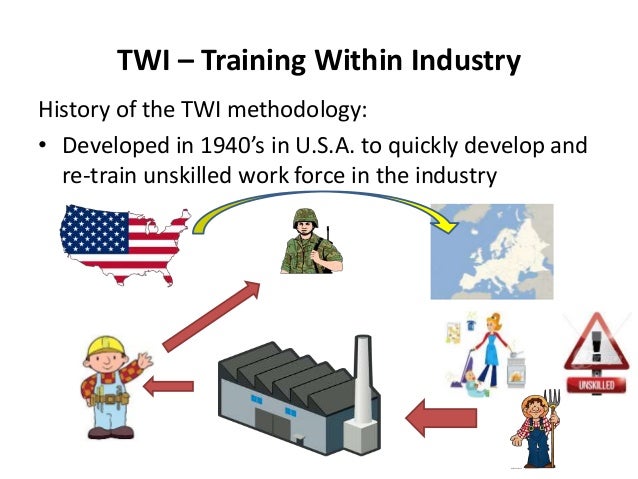

Teaching keywords TWI is an essential element of Lean and continuous improvement programs around the world including the Toyota Production System. TWI Means Training Within Industry Training Within Industry programs can create a culture of continuous improvement and repeatable success for your organization. What is Training Within Industry The origin of the program dates back to the early 40s of the last century when after the Nazi invasion of France in June 1940 the US realized that a world war In my view they are pure gold if you have to manage a shop floor. Read on to learn more. Training within Industry or TWI for short was a US program during World War II. TWI is the world s largest training organisation in welding underwater welding inspection and NDT servicing all major industry sectors with internationally recognised certifications.

While the ideas date to the 1940s they are still very relevant. Training Within Industry is the lean approach to training has been used by Toyota and other manufacturers throughout the world for decades and still has valuable lessons that can be put to use in training today. The Training Within Industry TWI program is a program which supports the development of management skills of experienced operational employees and low and middle management superiors. And what does it have to do with lean It significantly improved industrial production and helped the Allies to win the war. Training Within Industry TWI TWI is a dynamic program of hands-on learning and practice teaching essential skills for supervisors team leaders and anyone who directs the work of others. And played an important role in boosting the industrial production to the level necessary to win the war. JS provides a framework for supervisors to involve employees in identifying and eliminating potential hazards.

Find out how the TWI Institute can deliver the tools for cultural transformation for your organization. The Job Safety JS programme is an additional TWI programme that focuses on health and safety. The original Training Within Industry TWI Program was developed around 1940 in the U.S. JS was developed in Japan and although it was not part of the original TWI program it plays a crucial role in the industry today. About TWI Programs The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel.

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

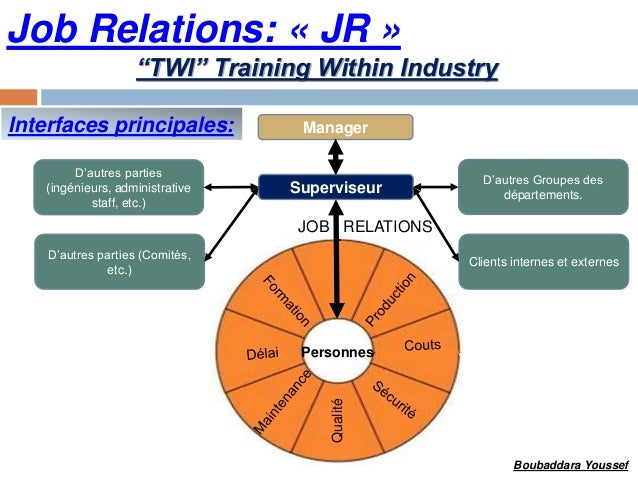

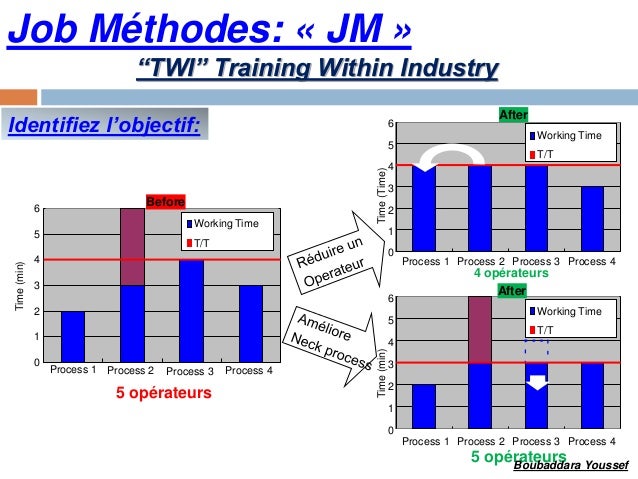

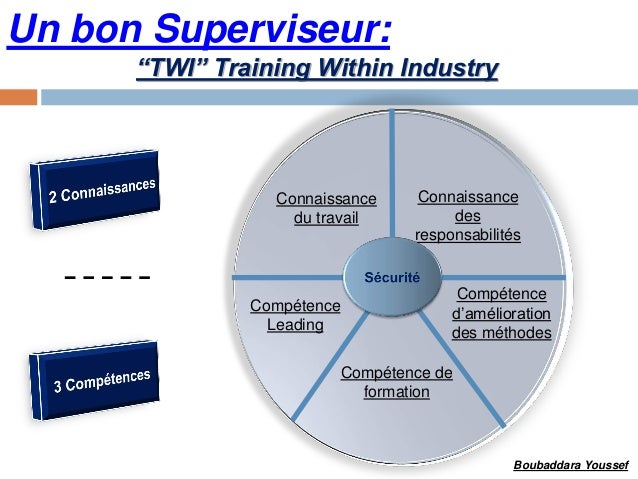

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara.

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Training Within Industry Program TWI Frameworks

Download Full Resolution

The TWI program has proven to be effective in providing shopfloor supervisors and team leaders with the skills they need to engage people in Lean activities. This presentation is a collection of PowerPoint diagrams tools and templates used to convey various Training Within Industry TWI frameworks models. The Training Within Industry TWI program is one of the most popular approaches to developing the skills of experienced operators and leaders in instructing improving and problem-solving. One TWI method is TWI Job Instruction JI which is focused on conducting on-the-job training. If you had purchased our TWI Program training program all the diagrams pocket cards and templates listed here were The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. NOTE If you had purchased our TWI Program training program all the diagrams pocket cards and templates listed here were already included in the package and you need not purchase them again. THIS TWI FRAMEWORKS COLLECTION INCLUDE 1. TWI Frameworks PowerPoint format 2. Job Instruction Breakdown Sheet Word format 3. Training Within Industry TWI TWI is a dynamic program of hands-on learning and practice teaching essential skills for supervisors team leaders and anyone who directs the work of others. TWI is an essential element of Lean and continuous improvement programs around the world including the Toyota Production System. Not that long ago we wrote an an overview of Training Within Industry TWI . As that article explains TWI was a job training program created by the U.S. government during World War II. And as it turns out it had a strong influence on the development of lean manufacturing in Japan. TWI delivers rapid ROI. Training within Industry boosts business results providing a fast return on investment in leadership development. TWI skills stabilise process performance motivate employees and have generated more improvement with less effort than any other leadership training system. The TWI programs follow a standardized four-step process that is simple straight forward and easy to implement. Small class sizes keep everyone involved en create an informal atmosphere. TWI Institute certified trainers assure training is delivered to quality standards and that the TWI methodology is followed. The Job Safety JS programme is an additional TWI programme that focuses on health and safety. JS provides a framework for supervisors to involve employees in identifying and eliminating potential hazards. JS was developed in Japan and although it was not part of the original TWI program it plays a crucial role in the industry today.

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia.

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Boubaddara Youssef TWI Training Within Industry

Download Full Resolution

TWI Training Within Industry Boubaddara Youssef 32. Job Relations JR TWI Training Within Industry Les types des probl mes face aux Superviseurs Un employ perd l int r t pour le travail. TWI Introduction Presentation With Case Studies 1. IntroductionTWI was developed in the 1940s by a team of US training professionals inresponse to the shortage of skilled workers during war time. There was aneed to establish an efficient highly skilled workforce in a very short spaceof time. We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime. To get more knowhow about training programs I want to dive into some different kind of methods and compare one to another. For now I know a little bit about the TWI-progam Training within industry . TWI Training Within Industry Training Certificate CSWIP Welding. SNT UT RT MT PT level II Inspector Non Destructive Examination. BEN YOUSSEF Moncef Senior E I Technician chez Shell Tunisia Upstream. Daniel Pluck HSSE Manager at OMV Tunisia. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering Boubaddara Youssef Guide pour la mise en place d un syst me HSE Youssef Boubaddara. Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. Organizing for Lean Autonomy Recursion and Cohesion Benjamin Sagalovsky. Boubaddara Youssef Mise en place d un SMQ par Mme Debethune Human Factors and Ergonomics Industrial Engineering and Manufacturing. Human Factors in Simulation and Training. The Foundation of Lean Donald A. Dinero The Training Within Industry TWI This training presentation is closely based on the original TWI training manuals from the National Archives. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting Boubaddara Youssef TWI Training Within Industry Youssef Boubaddara. 113-slide PowerPoint deck and supporting Excel workbook. The Lean - Standard Work Training Module includes 1. MS PowerPoint Presentation including 113 slides covering the History of Lean Manufacturing Five Lean Principles The Seven Lean Wastes Kaizen Events Introduction to Lean Standard

Training Within Industry Audio Book

Download Full Resolution

The TWI Institute is your resource for Training Within Industry and Toyota Kata training implementation education and certification. Whether in healthcare manufacturing or a service business we have extensive experience to support you along every step of your journey. Training Within Industry Audio Book. Posted on February 12 2017 February 13 2017 Author business901 Leave a comment. This is a collection of Business901 podcasts on Training within Industry. It is about 2-hours in length and features the following guests Be our guest in downloading the Roots of Lean book. The only thing we ask is that you let us know who s reading along with us Fill out the simple form below and you will be emailed a download link. Or if you prefer you can purchase a copy of the book here. FREE shipping on qualifying offers. Training Within Industry The Foundation of Lean In this article we re going to look at another aspect of lean manufacturing Training Within Industry TWI . Training Within Industry is the lean approach to training has been used by Toyota and other manufacturers throughout the world for decades and still has valuable lessons that can be put to use in training today. Read on to learn more. His studies and talks on TWI led to his writing the book Training Within Industry The Foundation of Lean published by Productivity Press 2005. This book won a Shingo Prize for Research in 2006. His book TWI Case Studies Standard Work Continuous Improvement Teamwork was published in April 2011. Training within Industry or TWI for short was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s they are still very relevant. In my view they are pure gold if you have to manage a shop floor. The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. What is Training Within Industry And what does it have to do with lean I know a lot about Lean. Throw out any lean term and I ll define it describe it and explain its place in the lean toolbox. TWI Means Training Within Industry Training Within Industry programs can create a culture of continuous improvement and repeatable success for your organization. Find out how the TWI Institute can deliver the tools for cultural transformation for your organization. About TWI Programs

A Historical Understanding of LEAN and Six Sigma OSHA

Download Full Resolution

Understanding the Lean Six Sigma Framework Safety Lean Six Sigma is a framework with which to achieve an injury free workplace. It is the combination of two powerful approaches to management. Lean Six Sigma Safety creates a framework that combines the best of both approaches to assist in managing safety by focusing on Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation. It combines lean manufacturing lean enterprise and Six Sigma to eliminate the eight kinds of waste Defects Over-Production Waiting Non-Utilized Talent Transportation Inventory Motion and Extra-Processing. Six Sigma was first introduced in 1986 by an engineer at Motorola named Bill Smith.Six Sigma is a methodology that focuses on measuring quality and aiming for perfection. The techniques and tools used for process improvement and eliminating defects are the core of Six Sigma. While the methodology began in the manufacturing industry today these techniques are used in virtually every type of This lesson looks at the history of Lean Six Sigma how this methodology has evolved over the years and the impact it has had on quality management in organizations. This video will help you better understand the Six Sigma methodology by applying the DMAIC framework cycle within a business model. A simple explanation of Six Sigma PECB. Lean Six Sigma Lean vs Six Sigma What s the Difference Use Cases. The History of Six Sigma. Lean Six Sigma For well defined processes that contain waste and there is a desire to change the process completely. Value stream mapping is used to identify the value and waste in the current process and then Six Sigma statistical methods are used to Some of these decisions if made without an understanding or appreciation for the complex systems at work may lead to incidents and possible injury and losses. Lean Six Sigma and Safety. Applying Lean Six Sigma thinking to safety has tremendous possibility and potential. Lean Six Sigma provides a framework for integrating safety into operations. With the right metrics SQDCM safety quality delivery cost morale boards can and should be used on the floor to enhance strategic development and the power of your Gemba walks. This displays a lack of Lean understanding. iSixSigma is your go-to Lean and Six Sigma resource for essential information and how-to knowledge. Six Sigma and Lean manufacturing are often mentioned in the same capacity there s even a methodology called Lean Six Sigma And while it s true that both methodologies have the same goal creating quality products at the best possible cost for customers each utilizes different approaches to get there. A Lean Six Sigma Green Belt possesses a thorough understanding of all aspects of the Lean Six Sigma Method including competence in subject matters contained within the phases of Define Measure Analyze Improve and Control DMAIC as defined by the IASSC Lean Six Sigma Green Belt Body of Knowledge .

Training Within Industry for the 21st Century

Download Full Resolution

How about a program that does for senior leaders today what Training Within Industry did for Japanese management in the 50s ask Jeff Morrow and Patrick Graupp. In this still young new century we must take the wisdom of the past and apply it effectively to the challenges of the new age. TWI for the 21st Century Digital On-the-Job Training. 13 min read - published on April 29 2019. As manufacturing processes become faster more complex and increasingly digitized learning on the shop floor needs to facilitate standard work and keep pace with the new world of industry 4.0. Training Within Industry always pairs one student TWI for the 21st Century Are Coaching Networks the future Mila Budeva Oct 23 2018. The US established the Training within Industry TWI Services as part of the War Manpower Commission in the summer of 1940. At the time the US faced a significant challenge how to increase industrial production of wartime materials while the industrial Tom Whelan Ph.D. director of corporate research shares insights from a research report on revising the 70-20-10 model for the 21st-century learning organization. Episode 2 The Gender Gap in Leadership Training How Learning and Development Can Help Break the Glass Ceiling industry partners clinicians patient advocates experts in regu-latory affairs and bioethicists among others would foster more successful translation from the bench than in the past. The increasingly transdisciplinary future of neuroscience makes it Neuroscience Training for the 21st Century Training within Industry or TWI for short was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s they are still very relevant. In my view they are pure gold if you have to manage a shop floor. Trainings Within Industry TWI Soft Skills Training R D series Books and Webinars Training Schedule Register For Training Onsite Registration Quality Digest - Documented Management Systems for the 21st Century Weninar. Webinar Title Quality Digest - Documented Management Systems for the 21st Century. Along with LEI s workshop TWI Job Instruction the Job Relations Training for Leaders class provides an overview of another component of the Training Within Industry Program which was created by the United States during World War II and has been used by Toyota and other Japanese companies for over 50 years to develop leaders and an exceptional workforce. Donald Dinero from TWI Learning Partnership offers fundamental skills training which helps to stabilize an organization preparing it to seriously begin its Lean journey. The Training Within Industry TWI program is a program which supports the development of management skills of experienced operational employees and low and middle management superiors. The origin of the program dates back to the early 40s of the last century when after the Nazi invasion of France in June 1940 the US realized that a world war

The Training Within Industry Job Instruction JI Program

Download Full Resolution

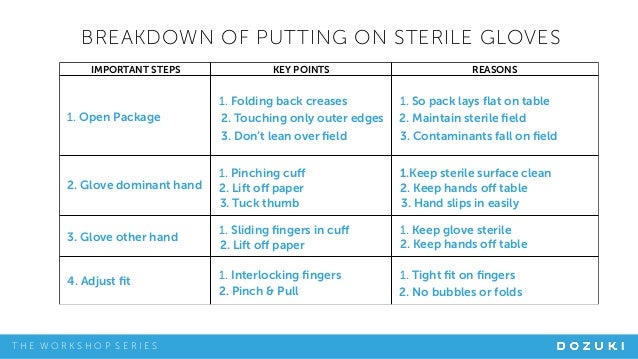

The TWI Job Relations JR Program Why Is JR Necessary In the Shingo-award winning book Training Within Industry The Foundation of Lean by Donald A. Dinero Dinero explains that . Addressing employee relations or how you work with other people may seem intuitive but when it comes to addressing personnel issues most managers need training. The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. The Training Within Industry TWI program is one of the most popular approaches to developing the skills of experienced operators and leaders in instructing improving and problem-solving. One TWI method is TWI Job Instruction JI which is focused on conducting on-the-job training. JI training teaches supervisors how to instruct the people doing the jobs. This training includes explaining to workers why their jobs are important breaking down the job into logical steps and key points and teaching the correct method of performing the task confirming that the workers can do the task on their own and following up to confirm that standard work is TWI Training Within Industry menjadi fondasi bagi pengembangan produktivitas industry Shopfloor Excellence program yang mendorong setiap frontline supervisor manager untuk menciptakan budaya produktivitas dengan focus pada kemampuan peningkatan kompetensi standard kerja Job Instruction JI pelatihan yang mampu meningkatkan prose The TWI Job Instruction JI Program Teaching Workers Job Skills Quickly and Effectively. In the Shingo-award winning book Training Within Industry The Foundation of Lean by Donald A. Dinero Dinero explains that many companies train new hires or current employees who need to learn new skills by pairing the worker with a more experienced worker who already has the desired skill. TWI Training Within Industry menjadi fondasi bagi pengembangan produktivitas industry Shopfloor Excellence program yang mendorong setiap frontline supervisor manager untuk menciptakan budaya produktivitas dengan focus pada kemampuan peningkatan kompetensi standard kerja Job Instruction JI pelatihan yang mampu meningkatkan prose Training Within Industry Job Instruction or TWI-JI has been a very successful job training program since 1940. The now many certified Instructors have been taught to breakdown jobs into Important Steps Key Points and the Reasons for those key points. The job breakdown is really the heart of the TWI-JI program. Training Within Industry - Job Instruction Many companies solve their problems by working on those problems in a targeted way. In retrospect these problems could have been prevented by structurally securing processes. However this appears to be a hell of a job for standardizing work processes is not a business case on set. Quickly training employees to do a job correctly safely and conscientiously. Job Instruction training is designed to develop basic stability of your processes standard work . This program teaches the method to instruct an operator how to perform a job correctly safely and conscientiously.

Training Within Industry TWI Nederland

Download Full Resolution

Training Within Industry TWI TWI is a dynamic program of hands-on learning and practice teaching essential skills for supervisors team leaders and anyone who directs the work of others. TWI is an essential element of Lean and continuous improvement programs around the world including the Toyota Production System. Het toepassen van TWI training Training Within Industry zorgt ervoor dat de inwerktijden en kansen op fouten minimaal worden en de prestatie maximaal. TWI Company past de TWI methode uit WO2 toe op een hedendaagse manier waarbij gebruik wordt gemaakt van moderne communicatiemiddelen. The original Training Within Industry TWI Program was developed around 1940 in the U.S. and played an important role in boosting the industrial production to the level necessary to win the war. Through a train-the-trainer program supervisors were taught to train and lead their people in the right way. TWI Means Training Within Industry Training Within Industry programs can create a culture of continuous improvement and repeatable success for your organization. Find out how the TWI Institute can deliver the tools for cultural transformation for your organization. About TWI Programs Peserta kompeten dalam menjalankan program TWI JI JM JR JS dan PS di tempat kerja. Peserta kompeten dalam mengaplikasikan dasar-dasar TWI dengan system manajemen mutu system manajemen industry lainnya sehingga bisa berjalan lebih efektif dan terintegrasi. Kurikulum Program Training Within Industry TWI. Konsep Dasar Training Within Industry TWI Peserta Training Within Industry TWI Kepala Pabrik Manager Superintendent dan Supervisor Fungsional Produksi Quality HRD Engineering Maintenance dan fungsi2 lain terkait Trainer dan Calon Trainer Manager dan Supervisor di bidang pengembangan Kompetensi Peningkatan Kinerja Perusahaan. 26 27 Maret 2020 In 2012 Kars graduated on his study Industrial Management by doing research on the Training Within Industry methods after which he successfully applied this method within several sectors. After a first JI Training in 2012 and a successful pilot in logistics Kars followed further trainings in TWI methods. The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. As the Toyota Production System was developed TWI was there underpinning its development and evolution. It s only in recent years that TWI s influence on TPS was recognized hidden in a complex system that evolved over decades. Enter Lean and what Training Within Industry has to do with it The TWI programs follow a standardized four-step process that is simple straight forward and easy to implement. Small class sizes keep everyone involved en create an informal atmosphere. TWI Institute certified trainers assure training is delivered to quality standards and that the TWI methodology is followed.

Training Within Industry TWI Programs - JI JM JR by

Download Full Resolution

Training Within Industry TWI is an integral part of Lean to reinforce the practice of Standard Work. Standardized work eliminates waste and provides a baseli Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising. The TWI Job Relations JR Program Why Is JR Necessary In the Shingo-award winning book Training Within Industry The Foundation of Lean by Donald A. Dinero Dinero explains that . Addressing employee relations or how you work with other people may seem intuitive but when it comes to addressing personnel issues most managers need training. Peserta kompeten dalam menjalankan program TWI JI JM JR JS dan PS di tempat kerja. Peserta kompeten dalam mengaplikasikan dasar-dasar TWI dengan system manajemen mutu system manajemen industry lainnya sehingga bisa berjalan lebih efektif dan terintegrasi. Kurikulum Program Training Within Industry TWI. Konsep Dasar Training Within Industry TWI Peserta kompeten dalam menjalankan program TWI JI JM JR JS dan PS di tempat kerja. Peserta kompeten dalam mengaplikasikan dasar-dasar TWI dengan system manajemen mutu system manajemen industry lainnya sehingga bisa berjalan lebih efektif dan terintegrasi. Kurikulum Training Within Industry TWI Konsep Dasar Training Within Industry TWI TWI Industry Program TWI Industry Program Job Instruction Training JI Teaches supervisors how to quickly train employees to do a job correctly safely and conscientiously Job Methods Training JM Teaches supervisors how to continuously improve the way jobs are done Job Relations Training JR Teaches supervisors how to evaluate and take proper actions to handle and to prevent people Job Relations JR is one of the modules of the original Training within Industry TWI program. It was actually developed at Harvard using case studies and for its time was groundbreaking in its idea that leadership can be learned Like most TWI modules it is sensible and useful. Two Days Workshop TRAINING WITHIN INDUSTRY The Complete TWI Programs JI JM JR JS PS Training. LEAN SUPERVISORY LEADERSHIP DEVELOPMENT. 29 30 Juli 2019 Epicentrum Walk Office Suite. Training Within Industry Programs Job Instruction Job Method Job Relation . TWI represents the roots and foundations of Lean Manufacturing.. During WWII TWI Training Within Industry developed in the United States training programs to improve proximity Manager skills because of the blatant lack of qualified workforce. The TWI Job Instruction JI Program Teaching Workers Job Skills Quickly and Effectively. In the Shingo-award winning book Training Within Industry The Foundation of Lean by Donald A. Dinero Dinero explains that many companies train new hires or current employees who need to learn new skills by pairing the worker with a more experienced worker who already has the desired skill. The TWI Problem Solving program consolidates and integrates the proven TWI methodologies of JI JR and JM under one plan for this purpose. Companies already employing one or more of the TWI skills can leverage these supervisory abilities and gain even more value from them.

Developing Job Breakdown Sheets according TWI methodology

Download Full Resolution

Simple but effective presentation prepared for a small company s key production persons foremen and team leaders to prepare the project of writing the full set of job breakdown sheets as first step of implementation of the TWI Training Within Industry methodology. The Training Within Industry TWI program is one of the most popular approaches to developing the skills of experienced operators and leaders in instructing improving and problem-solving. One TWI method is TWI Job Instruction JI which is focused on conducting on-the-job training. Developing Job Breakdown Sheets according TWI methodology. Posted 18 days ago Simple but effective presentation prepared for a small company s key production persons foremen and team leaders to prepare the project of writing the full set of job breakdown sheets as first step of implementation of the TWI Training Within Industry methodology. Developing Job Breakdown Sheets according TWI methodology. Posted 2 days ago Simple but effective presentation prepared for a small company s key production persons foremen and team leaders to prepare the project of writing the full set of job breakdown sheets as first step of implementation of the TWI Training Within Industry methodology. The Training Within Industry Job Method program provides a method for making more products of the same or higher quality in less time and or with fewer resources. As author Donald Dinero puts it TWI and Job Methods helps organizations make the best use of available resources to produce GREATER QUANTITIES of QUALITY PRODUCTS in LESS TIME. Job Breakdown sheet Job Breakdown sheet does not have to cover every conceivable step key point or motion It is not a Complete Instructions Manual for the job that can be handed to the employees. The purpose of the Job Breakdown sheet is to help the instructor organize the job in their mind and determine the Developing Job Breakdown Sheets according TWI methodology. Posted 15 days ago Simple but effective presentation prepared for a small company s key production persons foremen and team leaders to prepare the project of writing the full set of job breakdown sheets as first step of implementation of the TWI Training Within Industry methodology. Developing Job Breakdown Sheets according TWI methodology. Posted 4 days ago Simple but effective presentation prepared for a small company s key production persons foremen and team leaders to prepare the project of writing the full set of job breakdown sheets as first step of implementation of the TWI Training Within Industry methodology. The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. The TWI Job Instruction program teaches supervisors how to quickly train employees to do a job correctly safely and conscientiously. This tried and tested methodology is based on the 4-Step Method of Job Instruction and utilizes tools such as the Job Breakdown Sheet and Training Timetable.

Overview of Training Within Industry TWI by Operational

Download Full Resolution

Multipliers Spread the Training The TWI Program utilizes a standard method to Train people from industry to become TWI Trainers TWI Trainers train the people who direct the work of others supervisors team leaders managers etc. Supervisors spread the training to other people in the workplace by involving them as required in Overview of Training Within Industry TWI by Operational Excellence Job Application Template 6 Sigma Operational Excellence Lean Manufacturing Lean Six Sigma Change Management Scientific Method Jab How To Apply Training within Industry or TWI for short was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s they are still very relevant. In my view they are pure gold if you have to manage a shop floor. Peserta Training Within Industry TWI Kepala Pabrik Manager Superintendent dan Supervisor Fungsional Produksi Quality HRD Engineering Maintenance dan fungsi2 lain terkait Trainer dan Calon Trainer Manager dan Supervisor di bidang pengembangan Kompetensi Peningkatan Kinerja Perusahaan. 26 27 Maret 2020 TWI programs emphasise practical skills and habits not just knowledge that can be applied straight away in daily work and generate results quickly. The streamlined Training within Industry format with five short TWI training sessions per programme makes picking up new leadership skills a breeze. Training Within Industry TWI is an integral part of Lean to reinforce the practice of Standard Work. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting The firm s mission is to create business value for organizations through innovative operational excellence management training and Sep 7 2016 - Training Within Industry TWI programs. See more ideas about Operational excellence Programming and Process improvement. TWI JM training program. Overview of Training Within Industry TWI by Operational Excellence Consulting by OPERATIONAL EXCELLENCE CONSULTING via slideshare The Training Within Industry TWI service was created by the United States Department of War running from 1940 to 1945 within the War Manpower Commission.The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional mat riel. In this article we re going to look at another aspect of lean manufacturing Training Within Industry TWI . Training Within Industry is the lean approach to training has been used by Toyota and other manufacturers throughout the world for decades and still has valuable lessons that can be put to use in training today. Read on to learn more.

Overview of Training Within Industry TWI by Operational

Download Full Resolution

Multipliers Spread the Training The TWI Program utilizes a standard method to Train people from industry to become TWI Trainers TWI Trainers train the people who direct the work of others supervisors team leaders managers etc. Supervisors spread the training to other people in the workplace by involving them as required in Overview of Training Within Industry TWI by Operational Excellence Job Application Template 6 Sigma Operational Excellence Lean Manufacturing Lean Six Sigma Change Management Scientific Method Jab How To Apply Training within Industry or TWI for short was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s they are still very relevant. In my view they are pure gold if you have to manage a shop floor. Peserta Training Within Industry TWI Kepala Pabrik Manager Superintendent dan Supervisor Fungsional Produksi Quality HRD Engineering Maintenance dan fungsi2 lain terkait Trainer dan Calon Trainer Manager dan Supervisor di bidang pengembangan Kompetensi Peningkatan Kinerja Perusahaan. 26 27 Maret 2020 Training Within Industry TWI is an integral part of Lean to reinforce the practice of Standard Work. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting The firm s mission is to create business value for organizations through innovative operational excellence management training and Sep 7 2016 - Training Within Industry TWI programs. See more ideas about Operational excellence Programming and Process improvement. TWI JM training program. Overview of Training Within Industry TWI by Operational Excellence Consulting by OPERATIONAL EXCELLENCE CONSULTING via slideshare

Overview of Training Within Industry TWI by Operational

Download Full Resolution

Multipliers Spread the Training The TWI Program utilizes a standard method to Train people from industry to become TWI Trainers TWI Trainers train the people who direct the work of others supervisors team leaders managers etc. Supervisors spread the training to other people in the workplace by involving them as required in Overview of Training Within Industry TWI by Operational Excellence Job Application Template 6 Sigma Operational Excellence Lean Manufacturing Lean Six Sigma Change Management Scientific Method Jab How To Apply Training Within Industry TWI Job Relations Program by Operational Excellence Consulting The firm s mission is to create business value for organizations through innovative operational excellence management training and consulting solutions. OEC takes a unique beyond the tools approach to enable clients develop internal The Training Within Industry TWI program is a program which supports the development of management skills of experienced operational employees and low and middle management superiors. The origin of the program dates back to the early 40s of the last century when after the Nazi invasion of France in June 1940 the US realized that a world war Training Within Industry TWI is an integral part of Lean to reinforce the practice of Standard Work. Training Within Industry TWI Programs - JI JM JR by Operational Excellence Consulting The firm s mission is to create business value for organizations through innovative operational excellence management training and Training within Industry or TWI for short was a US program during World War II. It significantly improved industrial production and helped the Allies to win the war. While the ideas date to the 1940s they are still very relevant. In my view they are pure gold if you have to manage a shop floor. An Overview of TWI Training Within Industry is a program originally developed to service the needs of the United States government in a climate of rapid change and constantly increasing demands during the war. The system was lean and tightly structured and it produced some amazing results which makes it a bit unusual that Training Within Industry TWI is a method with an answer employee is the responsibility of the operational management. Support in the process is desired however choosing what has to be trained and when stays the responsibility of the good training standard task analysis are taught. Training Within Industry TWI Job Methods Program by Operational Excellence Consulting The firm s mission is to create business value for organizations through innovative operational excellence management training and consulting solutions. OEC takes a unique beyond the tools approach to enable clients develop internal This presentation is a collection of PowerPoint diagrams tools and templates used to convey various Training Within Industry TWI frameworks models. They include Job Instruction Breakdown Sheet Job Instruction Training Timetable Job Methods Breakdown Sheet simple Job Methods Breakdown Sheet 8.5x11 Job Methods Breakdown Sheet 8.5x14

Training Within Industry TWI Workshop USG Blog United

Download Full Resolution

Training Within Industry TWI Workshop was conducted on 11 18 April 2015. TWI is apart of people development program along USG Lean Journey. The participant learned a To improve work processes in a structured and focused manner JM b To establish the best practice to perform the tasks ECAS The TWI Institute is your resource for Training Within Industry and Toyota Kata training implementation education and certification. Whether in healthcare manufacturing or a service business we have extensive experience to support you along every step of your journey. Lessons Learned Training Within Industry TWI in the United States by Bob Wrona TWI Institute The Second Coming TWI Primer by Dwayne Butcher Lean Frontiers The Training Within Industry Approach Resurges in the U.S. Workforce by TWI Summit Presenter Denny Hall in ASTD s T D Magazine Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement. Training Within Industry after the workshop practice session. In fact TWI is not new. TWI was established in 1940 in the United States by the National Defense Advisory Committee. Although the name is not as sexy as Lean Six Sigma Workshop Overview Learn the Training Within Industry methods of Job Instruction used by Toyota to train its people in the Toyota Production System. This two-day course is accredited by TWI and will teach the Job Instruction skills JI as used by Toyota and over 10 million workers in Japan have taken TWI programmes. Standard O-peration With Training Within Industry TWI RM 10 478.00 8 May 2015 United Sweethearts Garment Sdn Bhd Sungai Bakap Sungai Petani Nepal Earthquake Donation RM 20 000.00 21 May 2015 United Sweethearts Garment Sdn Bhd Sungai Bakap Sungai Petani Jobs Clearing System E-PPA System RM 850.00 31 May 2015 FMM Heritage Green TWI Means Training Within Industry Training Within Industry programs can create a culture of continuous improvement and repeatable success for your organization. Find out how the TWI Institute can deliver the tools for cultural transformation for your organization. About TWI Programs Find the latest books on Training Within Industry Kata Job Instruction and more from our TWI Institute authors as well as Toyota Production TPS Kaizen Leadership and Corporate Strategy and Lean TWI in Healthcare from other leading authors. Training Within Industry s rich history originated in the United States in the 1940s where the program was a resounding success boosting industrial production of war material beyond expectations. The program was born out of the need to rapidly train unskilled workers entering the war production workforce as many skilled laborers went off to war. Training Within Industry TWI The Foundation of Standardized Work Continuous Improvement Contributed by Allan Ung on January 9 2015 in Operations Supply Chain In September 1990 my colleague and I participated in a technical training program for instructors held at the Panasonic Overseas Training Center and the Production Engineering

Lean Manufacturing and Training A Look at Training

Download Full Resolution

In this article we re going to look at another aspect of lean manufacturing Training Within Industry TWI . Training Within Industry is the lean approach to training has been used by Toyota and other manufacturers throughout the world for decades and still has valuable lessons that can be put to use in training today. Read on to learn more. It wouldn t be a full comparison of lean manufacturing and job training if we didn t touch on continuous improvement. Continuous improvement is a hallmark of lean manufacturing and goes hand-in-hand with reducing waste and increasing value. Likewise you should aim to continuously improve your training program as well. In this article we re going to look at another aspect of lean manufacturing Training Within Industry TWI . Training Within Industry is the lean approach to training has been used by Toyota and other manufacturers throughout the world for decades and still has valuable lessons that can be put to use in training today. Lean certified professionals can look out for job roles related to the quality sector Any experienced or fresh candidates can take up the training as a Lean Manufacturing certification course adds a greater value on their resumes and helps them to start deploying What is Lean Six Sigma Black Belt Certification in Manufacturing Lean Six Sigma Black Belt Training and Certification in Manufacturing will positively impact your career by providing a deep understanding of not only the methodology but the leadership role within Six Sigma. Our lean manufacturing training courses provide a unique experience to help you implement and sustain a lean culture within your organization. Courses range from one-day introductory courses run at your premises through to week-long lean training courses held in a Toyota kaizen training facility and associated factories in Japan.

Gemba Academy Training Within Industry TWI

Download Full Resolution

Training Within Industry or TWI for short is a set of three hands-on go to gemba style training methodologies developed by the United States TWI Service at the beginning of World War II. Due to the war effort the US lost most of their skilled workforce to military service while at the same Training Within Industry or TWI for short is a set of three hands-on go to gemba style training methodologies developed by the United States TWI Service at the beginning of World War II. These three methods are Job Instruction JI Job Relations JR and Job Methods JM . Job Instruction JI Our partnership with Gemba Academy has been critical in helping advance Lean Six Sigma at Amway. The video library compliments our existing training programs and helps deepen continuous improvement mastery not only within our Green Belt Black Belt community but other employees who are expanding their process improvement capabilities. Gemba Academy is the best provider of Lean and Six Sigma training including online on-site coaching and certifications. Home Learning Library School of Lean TWI - Training Within Industry Job Methods JM Day 1 Job Methods Overview. Gemba Academy 118 463 views 12 06 1 513 videos Play all Hip Hop Songs 2020 - Best Hip Hop Playlist 2020 - Hip Hop 2020 - Rap 2020 Arsenio Sarmiento The first overview video of Gemba Academy s new Training Within Industry TWI course can now be watched without registration Preview the 1st Training Within Industry Video. The rest of the videos on TWI and Job Instruction will be available later this month Gemba Academy is the best provider of Lean and Six Sigma training including online on-site coaching and certifications. Home Learning Library School of Lean TWI - Training Within Industry Job Instruction JI For Facilitators Day 1 Job Instruction Overview. Job Instruction JI For Facilitators Without sounding overly dramatic I m fairly certain my content development team and I are working on the most important Gemba Academy course we ve ever produced. This new course will be focused on the Job Relations JR aspect of TWI Training Within Industry . As an aside we ve actually released some good JR Gemba Academy is the best provider of Lean and Six Sigma training including online on-site coaching and certifications. Home Learning Library School of Lean TWI - Training Within Industry Job Instruction JI For Learners Day 1 Job Instruction Overview. Job Instruction JI For Learners Without sounding overly dramatic I m fairly certain my content development team and I are working on the most important Gemba Academy course we ve ever produced. This new course will be focused on the Job Relations JR aspect of TWI Training Within Industry .

Training Within Industry TWI Frameworks PowerPoint

Download Full Resolution

NOTE If you had purchased our TWI Program training program all the diagrams pocket cards and templates listed here were already included in the package and you need not purchase them again. THIS TWI FRAMEWORKS COLLECTION INCLUDE 1. TWI Frameworks PowerPoint format 2. Job Instruction Breakdown Sheet Word format 3. This presentation is a collection of PowerPoint diagrams tools and templates used to convey various Training Within Industry TWI frameworks models. Training Within Industry TWI Frameworks Diagrams Tools Templates for Job Instruction Job Methods Job Relations Job Safety Problem Solving TWI Frameworks PowerPoint format 2. Job Instruction Breakdown Sheet Word format Learn What Training Within This presentation is a collection of PowerPoint diagrams tools and templates used to convey various Training Within Industry TWI frameworks models. Training Within Industry TWI Frameworks Diagrams Tools Templates for Job Instruction Job Methods Job Relations Job Safety Problem Solving Buy and sell PowerPoint templates business frameworks presentation templates and more. Become a PowerPoint Guru by Dave Tracy Learn the methodologies frameworks and tricks used by Management Consultants to create executive presentations in the business world. Training Within Industry TWI Treacy Wiersema Value Disciplines Tuckman As the Toyota Production System was developed TWI was there underpinning its development and evolution. It s only in recent years that TWI s influence on TPS was recognized hidden in a complex system that evolved over decades. Enter Lean and what Training Within Industry has to do with it Training Within Industry - a key element of standardized work Standardization should be applied to processes which are special repeated frequently or which were selected for standardization due to e.g. high complexity. Slide No. 7 Standardized Work with TWI The TWI Institute is your resource for Training Within Industry and Toyota Kata training implementation education and certification. Whether in healthcare manufacturing or a service business we have extensive experience to support you along every step of your journey. Training Within Industry TWI - Improve shopfloor productivity and safety with the 4-step systematic approach to Job Instruction JI Job Methods JM and Jo Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising. This presentation is a collection of PowerPoint diagrams and templates used to convey 40 different Lean Enterprise frameworks and models. This presentation is a collection of PowerPoint diagrams and templates used to convey 40 different Lean Enterprise frameworks and models. TPM Training Within Industry TWI Value Stream Mapping

TWI Training Within Industry. Eliminar el desperdicio del

Download Full Resolution

Training Within Industry - TWI s un programa de desenvolupament per a supervisors de planta l objectiu del qual s augmentar la seva preparaci per tal que puguin desenvolupar efica ment les seves tasques de supervisi de la producci . Els cursos TWI desenvolupen les habilitats d instruir els treballadors d establir unes bones relacions amb ells i l habilitat de millorar m todes En los a os de la Segunda Guerra Mundial se crea TWI Training Within Industry como respuesta a la necesidad de entrenar a miles de mujeres y hombres en f bricas de EE.UU. de forma eficaz econ mica y asegurando la calidad del producto. TWI Training Within Industry se fundamenta en un m todo probado para dise ar el proceso de En los a os de la Segunda Guerra Mundial se crea TWI Training Within Industry como respuesta a la necesidad de entrenar a miles de mujeres y hombres en f bricas de EE.UU. de forma eficaz econ mica y asegurando la calidad del producto. TWI Training Within Industry se fundamenta en un m todo probado para dise ar el proceso de The Training Within Industry The Foundation of Lean by Donald A. Los preceptos b sicos de Lean son servir al cliente y eliminar el desperdicio. Otros preceptos incluyen desarrollar a los trabajadores en todos los niveles. El 20 del trabajo de preparaci n consist a en anotar la informaci n que s lo l conoc a. Training Within Industry La formaci n en las tareas del puesto seg n el m todo de Instrucci n del Trabajo permite Reducir el desperdicio los rechazos y los retrabajos mejora de calidad La aplicaci n del m todo TWI IT ayuda a eliminar las consecuencias de la formaci n deficiente y los frecuentes errores en la formaci n. eliminar ou tornar men or o que n o s o rele E quilibrat de l nies de muntatge en una empresa del sect or inform tic Training Qualification TWI Training Within Industry .

TWI - Training Within Industry - YouTube

Download Full Resolution

Developed by the US Government during World War II Training Within Industry TWI is a methodology to quickly train and develop new employees and supervisors. The methodologies are still Training Within Industry Job Instruction is a four-step method that teaches an individual how to do a job correctly safely and consistently while meeting all requirements. In this video LEI T tulo Training Within Industry. Hoja de instructions de trabajo Descripci n El el v deo se describe la hoja de instrucciones de trabajo dentro del programa traingin within industry TWI DER The TWI Institute is your resource for Training Within Industry and Toyota Kata training implementation education and certification. Whether in healthcare manufacturing or a service business we have extensive experience to support you along every step of your journey. As the Toyota Production System was developed TWI was there underpinning its development and evolution. It s only in recent years that TWI s influence on TPS was recognized hidden in a complex system that evolved over decades. Enter Lean and what Training Within Industry has to do with it Learn What Training Within Industry TWI is All About With Jim Huntzinger - Duration 16 36. Gemba Academy Recommended for you The original Training Within Industry TWI Program was developed around 1940 in the U.S. and played an important role in boosting the industrial production to the level necessary to win the war. Through a train-the-trainer program supervisors were taught to train and lead their people in the right way. You can do TWI without Lean but you cannot do Lean without TWI During the summer of 2013 Jim Huntzinger participated at the annual european TWI conference held in Billund Denmark.

Training Within Industry TWI 101 - Dozuki Workshop Series

Download Full Resolution

Training Within Industry TWI 101 - Dozuki Workshop Series 1. TRAINING WITHIN INDUSTRY GUEST EXPERT PATRICK GRAUPP 2. TRAINING WITHIN INDUSTRY GUEST EXPERT PATRICK GRAUPP 3. Origins of TWI 2. Practical Examples of TWI in Action 5. Training Within Industry TWI has been adopted by global companies like Toyota and LEGO. See how it can be applied to your workforce with this workshop with guest Patrick Graupp of the TWI Institute. Present instructions to users in clear concise and memorable ways to better train your teams with TWI. View this on-demand webinar to learn Including how-to write work instructions managing workforce training continuous improvement guides Check out our practical guide for how-to tackle Training Within Industry 101. Collecting E-signatures in Dozuki. Making standard work an industry standard. Dozuki builds software that helps companies implement a continuous Goodyear s Guide To Lean Product Development - Dozuki Workshop Series 1. Goodyear s Guide to Lean Product Development This presentation may contain con dential and or proprietary information. This presentation may not be copied or disseminated without the express written consent of the Goodyear Tire Rubber Company. Dozuki Workshop Training Within Industry TWI 101. Register for the next live Dozuki Workshop on 8 25 16 at 11am PDT. Learn how STE can help you provide accurate information reduce Cal Poly University s Lean Systems 101 - Dozuki Workshop Series 1 085 views . Cal Poly University s Lean Systems 101 CUSTOMER SATISFACTION BUSINESS SUCCESS RESPECT FOR PEOPLE Team Building Empowerment Cross Training Hoshin Supplier Relationships JIT Pull Flow TAKT Time Heijunka Cell Design SMED JIDOKA Poka-yoke And on Photography Basics How To Shoot Like A Pro - Dozuki Workshop Series 931 views. Share Like Download How To Shoot Like A Pro - Dozuki Workshop Series 1. Training Within Industry TWI 101 - Dozuki Workshop Series Dozuki Software. Free live-streamed educational seminars hosted by the Dozuki te Training With Industry TWI NAVSUPINST 1520.7B can be found at the SC Homepage on NKO Ready. Training With Industry TWI Supply Corps Administrative Board Flag-led convenes annually in May. Flash from the Chief is released in February with program deadlines and convene dates. This presentation is a collection of PowerPoint diagrams tools and templates used to convey various Training Within Industry TWI frameworks models. They include Job Instruction Breakdown Sheet Job Instruction Training Timetable Job Methods Breakdown Sheet simple Job Methods Breakdown Sheet 8.5x11 Job Methods Breakdown Sheet 8.5x14

No comments:

Post a Comment